To guarantee the long-term stable and efficient operation of your laser equipment, proper water circuit connection and lubrication maintenance are essential. Please follow the steps below carefully:

Ⅰ. Water Circuit Connection

Normal Temperature Circulation System

Connect the normal temperature outlet at the rear of the machine to the normal temperature outlet of the chiller.

Connect the normal temperature return port at the rear of the machine to the normal temperature return port of the chiller.

Low Temperature Circulation System

Connect the low temperature outlet at the rear of the machine to the low temperature outlet of the chiller.

Connect the low temperature return port at the rear of the machine to the low temperature return port of the chiller.

Water Filling & Power Connection

Fill the chiller with pure water or distilled water through the water inlet until the water level reaches the standard level zone (green area).

After filling, connect the chiller’s power cable to ensure proper system operation.

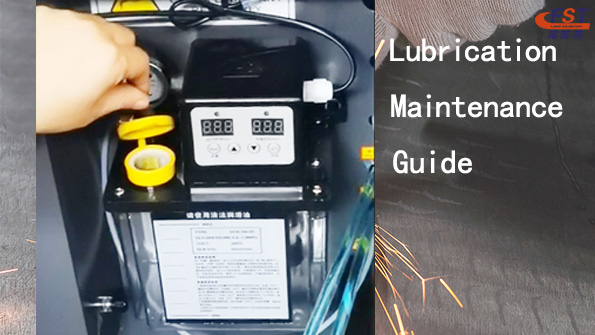

Ⅱ. Guide Rail Lubrication Maintenance

To keep the guide rails running smoothly and extend their service life:

Regularly apply an appropriate amount of specialized guide rail lubricant to prevent dry friction and abnormal noise.

Use a clean cloth to remove excess oil and dust, keeping the guide rails clean and smooth.

Tips

Proper water circuit connection and regular lubrication not only prevent overheating and wear but also significantly enhance the stability and precision of fiber laser cutting machine and welding operations.

Routine maintenance keeps your machine performing at its best—efficient, precise, and reliable!

Post time: Oct-28-2025