In the daily operation of a fiber laser cutting machine, the proper selection of auxiliary gases and the correct connection of gas pipelines play a crucial role in cutting quality, equipment stability, and service life. The following

outlines the standard gas requirements and pipeline connection instructions for the 3015 fiber laser cutting machine.

FIRST Types of Auxiliary Gases and Applications

Oxygen (O₂)

1.Purity Requirement: ≥ 99.95%. If the oxygen purity is insufficient (e.g., below 99.95%), it may cause unstable flame temperature, reduced cutting speed, severe oxidation of the cutting surface, and slag adhesion. These

issues not only affect processing efficiency but may also damage the nozzle due to accumulated slag.

2.Main Application: Carbon steel cutting.

3.Function: As a combustion-supporting gas, oxygen increases cutting speed. During cutting, it reacts with iron to generate additional heat, which facilitates rapid piercing and thick plate cutting.

Nitrogen (N₂)

1.Purity Requirement: ≥ 99.95%.

2.Main Application: Stainless steel, aluminum alloys, and other non-ferrous metals.

3.Function: As an inert gas, nitrogen prevents oxidation on the metal surface during cutting, ensuring a smooth and bright cut edge. It is ideal for applications requiring high-quality cut finishes.

Compressed Air (Air)

1.Purity Requirement: Air must be clean and dry, free from water, oil, and any impurities.

2.Main Application: Thin carbon steel and thin stainless steel.

3.Function: Compressed air is cost-effective and suitable for cutting medium-to-thin plates. It helps reduce production costs but is more appropriate where extremely high edge quality is not required.

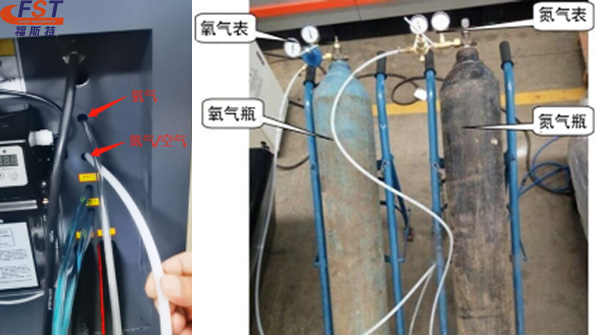

SECOND Gas Pipeline Connection

Oxygen Connection

1.The oxygen port at the rear of the machine should be connected to the oxygen cylinder via a pressure regulator (oxygen gauge).

2.Adjust the oxygen regulator output pressure to around 0.5 MPa to ensure stable cutting performance.

Nitrogen/Air Connection

1.The nitrogen/air port at the rear of the machine can be connected either to the nitrogen cylinder via a regulator or to an air compressor.

2.Adjust the nitrogen regulator output pressure to above 1.6 MPa.

3.The air compressor must be equipped with a refrigerated dryer and precision filter to ensure a clean and stable air supply.

THIRD Operational Precautions

1.Gas Purity Inspection

Regularly check gas purity to avoid cutting defects, oxidation discoloration, or contamination of optical components caused by substandard gas quality.

2.Pipeline Cleanliness and Sealing

Ensure pipelines are free from water, oil, and dust before connection.

Connections must be tight and secure to prevent gas leakage, which may result in insufficient pressure and poor cutting performance.

3. Pressure and Flow Control

Different materials and thicknesses require different gas pressures. Operators should adjust parameters according to specific process requirements.

Too low a pressure may lead to incomplete cuts or excessive burrs, while too high a pressure may cause unnecessary gas consumption or negatively affect cut quality.

4. Safety Precautions

Oxygen cylinders must be kept away from heat sources and flammable materials. They should be placed upright and securely fixed to prevent tipping.

When handling nitrogen or compressed air, operators should wear safety goggles and gloves to protect against potential high-pressure leaks.

Regularly inspect the gas supply system to ensure safety valves, regulators, and other components are functioning properly.

Conclusion

Proper selection and use of auxiliary gases are essential to ensure cutting quality and production efficiency with the 3015 laser cutting machine. Operators must strictly follow the requirements regarding gas purity, pressure,

and pipeline connections, while performing regular maintenance and inspections, to guarantee stable operation and optimal cutting performance.

Post time: Sep-24-2025