In the operation of the 3015 fiber laser cutting machine, the nozzle may appear small, but it plays a vital role in ensuring cutting precision, equipment longevity, and production efficiency. It not only directly impacts

cutting quality and machine lifespan but also relates to overall productivity and cost control. Mastering the proper selection and maintenance of nozzles is therefore essential for every operator. Today, let’s take a closer look

at the core functions, selection guidelines, and replacement procedures of the 3015 fiber laser cutting nozzle, helping production teams maintain precision throughout every cutting process.

Core Functions of the Nozzle

1. Protecting Optical Components

The nozzle effectively prevents molten material and debris from splashing upward during cutting, avoiding contamination or damage to the cutting head and protective lenses, thereby extending the equipment’s service life.

2. Enhancing Cutting Quality

By concentrating and controlling the flow of auxiliary gas, the nozzle ensures proper gas distribution. This leads to smoother, cleaner, and more precise cutting edges.

Relationship Between Nozzle Condition and Cutting Quality

The condition of the nozzle directly determines cutting performance.

If the nozzle is deformed, clogged, or contaminated, the gas flow becomes uneven, resulting in rough edges, unstable piercing, or reduced accuracy.

Operators should therefore clean the nozzle regularly and replace it immediately if any performance issues occur, ensuring consistent cutting quality.

Key Points in Nozzle Selection

Small-diameter nozzles: Higher gas velocity, stronger slag removal capability, ideal for thin sheet cutting, delivering finer cutting edges.

Large-diameter nozzles: Lower gas velocity, better suited for thick plate cutting at lower speeds. Using them for thin sheet high-speed cutting may cause molten splash and damage the protective lens.

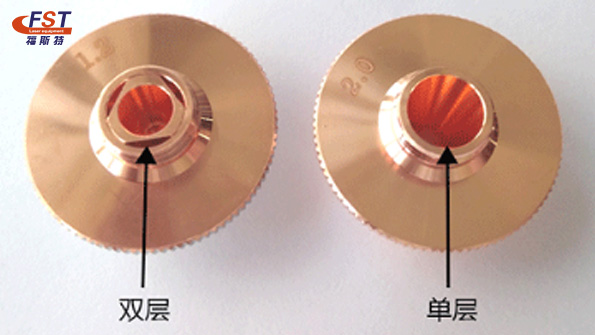

Single-layer nozzles: Commonly used for stainless steel cutting, providing concentrated gas flow and high edge smoothness.

Double-layer/Multilayer nozzles: Typically used for carbon steel cutting, ensuring more uniform gas distribution and stable cutting performance.

Nozzle Replacement Steps

1.Unscrew and remove the old nozzle.

2.Securely screw the new nozzle onto the nozzle connector.

3.After replacement, perform capacitive calibration to ensure the cutting head operates under optimal conditions.

Conclusion

For the 3015 fiber laser cutting machine, nozzle selection and maintenance may seem like minor details, but they directly affect laser eauipment, equipment lifespan, and production efficiency. By making the right

choices andconducting timely maintenance, manufacturers can fully unleash the efficiency and stability of their laser cutting equipment.

Post time: Sep-25-2025