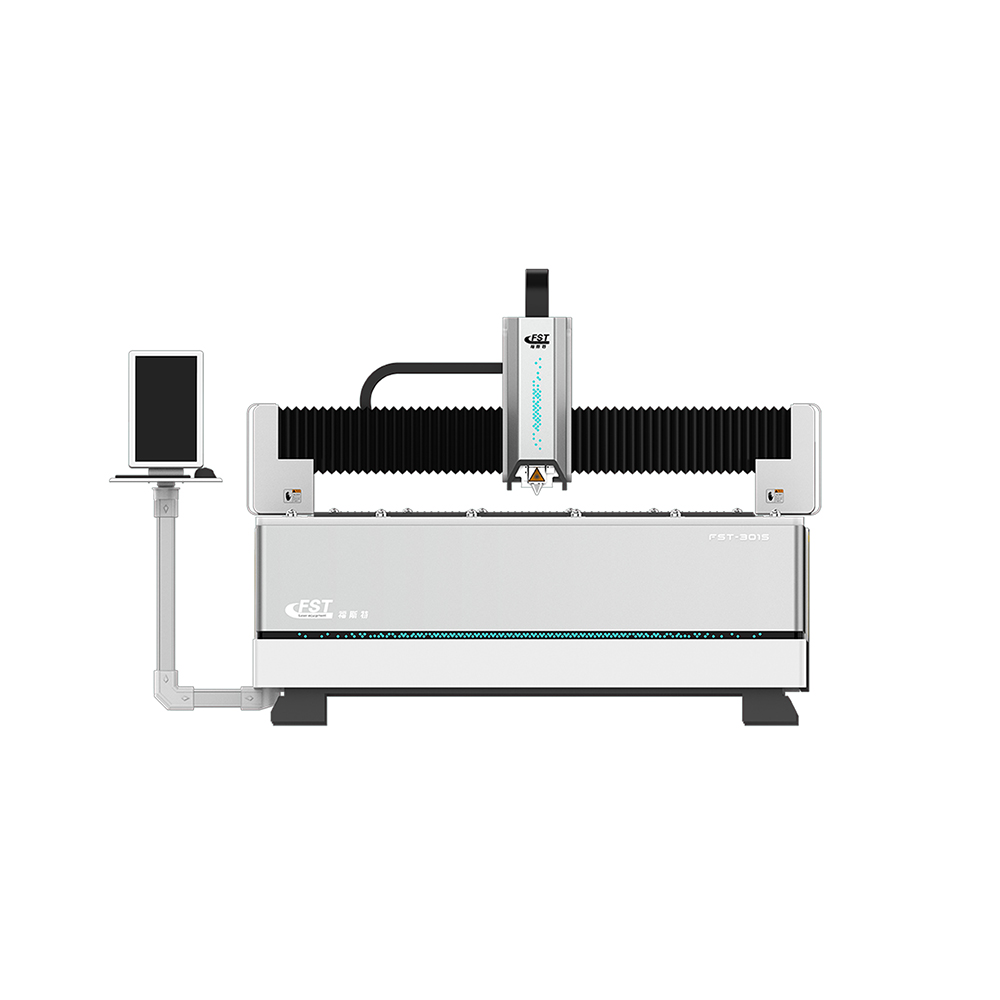

Manufacturer Of 6000w Fiber Laser Cutting - Flatbed Fiber laser cutting machine – Foster

Manufacturer Of 6000w Fiber Laser Cutting - Flatbed Fiber laser cutting machine – Foster Detail:

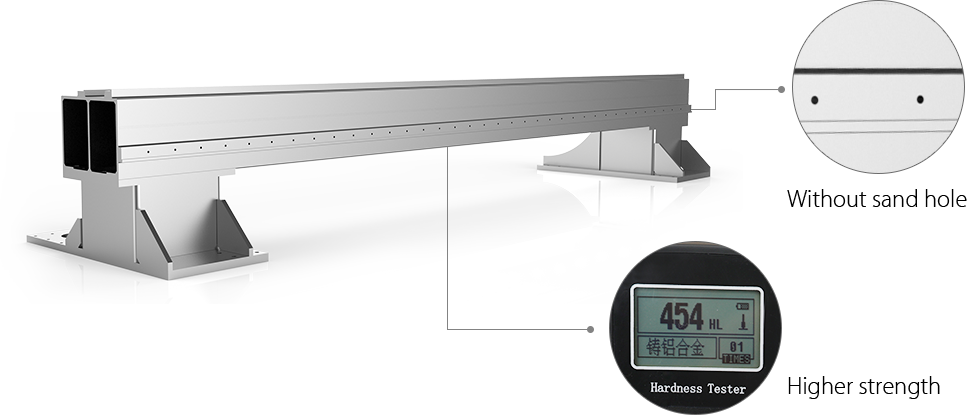

3rd Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed bypress extrusion molding. Aviation aluminum has many advantages, such as good toughness, lightweight , corrosion resistance, anti-oxidation, low density, and greatly increasehe processing speed.

● High speed:

The light crossbeam can ensure the machine have high moving speed and improve the processing efficiency.

● More efficient:

The aluminum profile beam of the aerospace industry makes the equipment have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

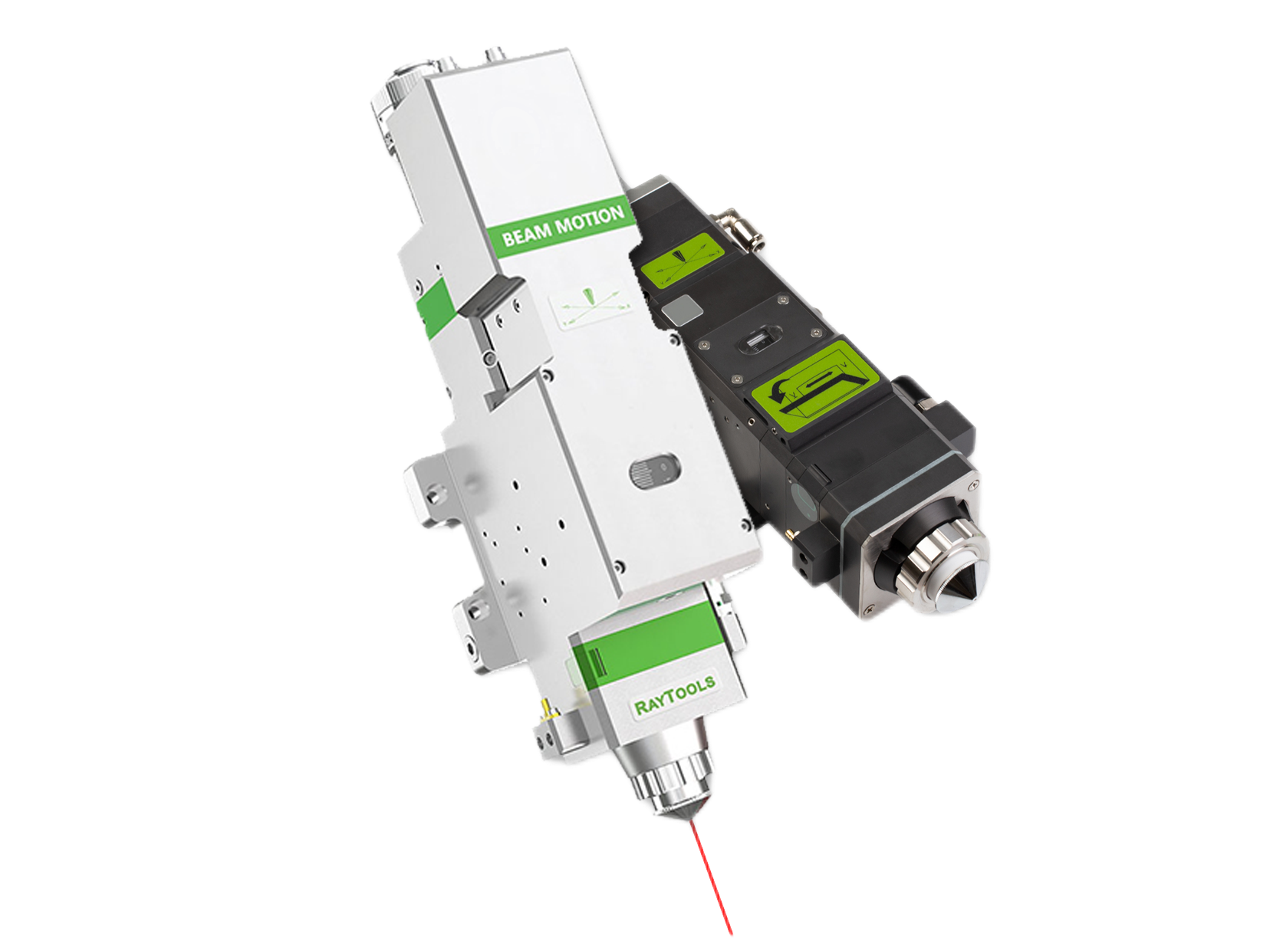

Laser Cutting Head

RAYTOOLS / WSX / PRECITEC (optional)

● Multiple Protection

3 protective lenses, highly effective collimating focus lens protection. 2-way optical water cooling extends the continuous working time effectively.

● High-precision

To successfully avoid step loss, a closed-loop stepping motor is used. The repetition accuracy is 1 M and the focusing speed is 100 m m / s. Dust-proof to IP65, with a patent-protected mirror cover plate and no dead angle.

● Various Brands Of Laser Head Are Available

We can provide all high quality laser heads. It has been tested by us for a long time.

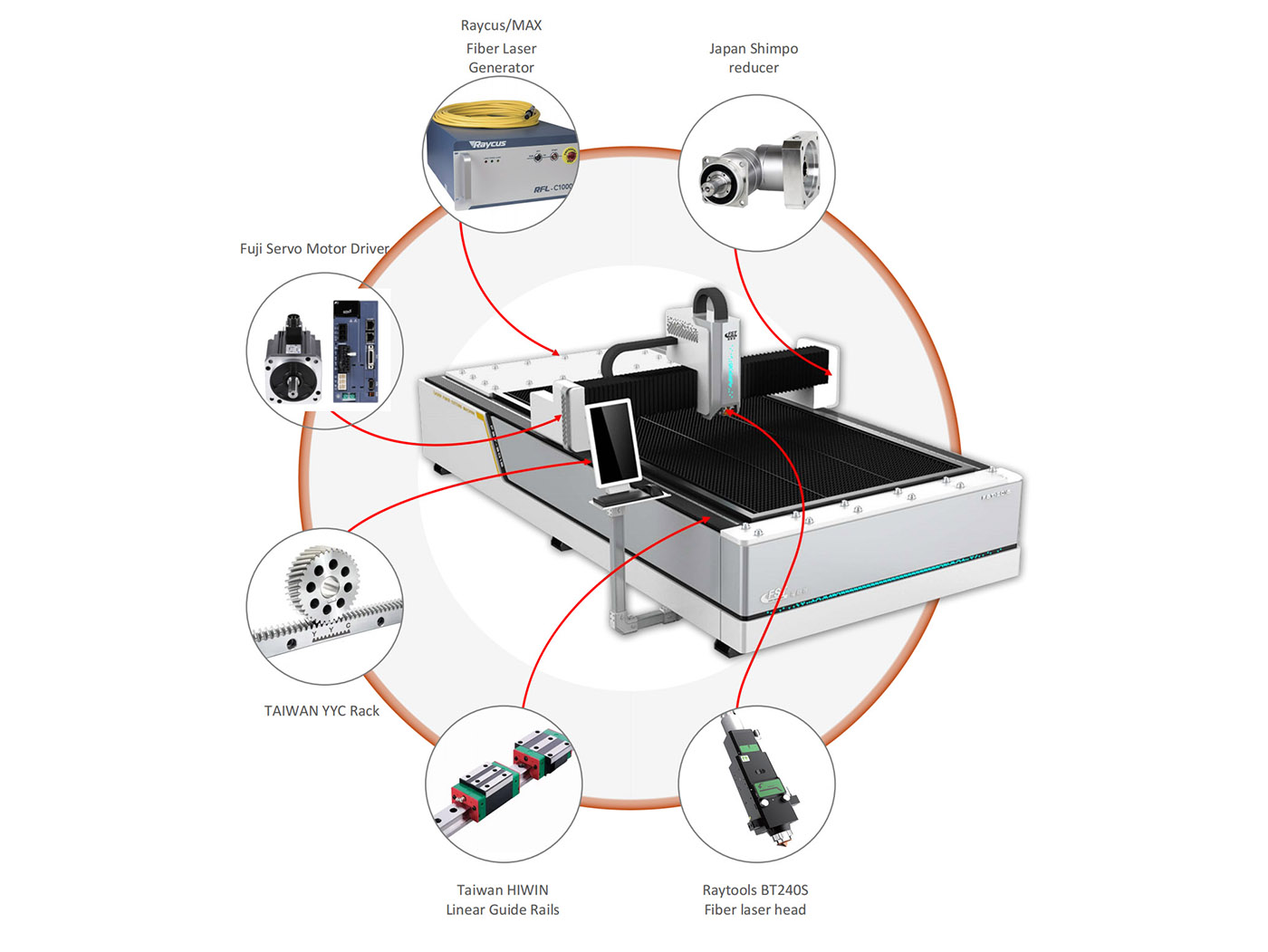

Detail Display Diagram

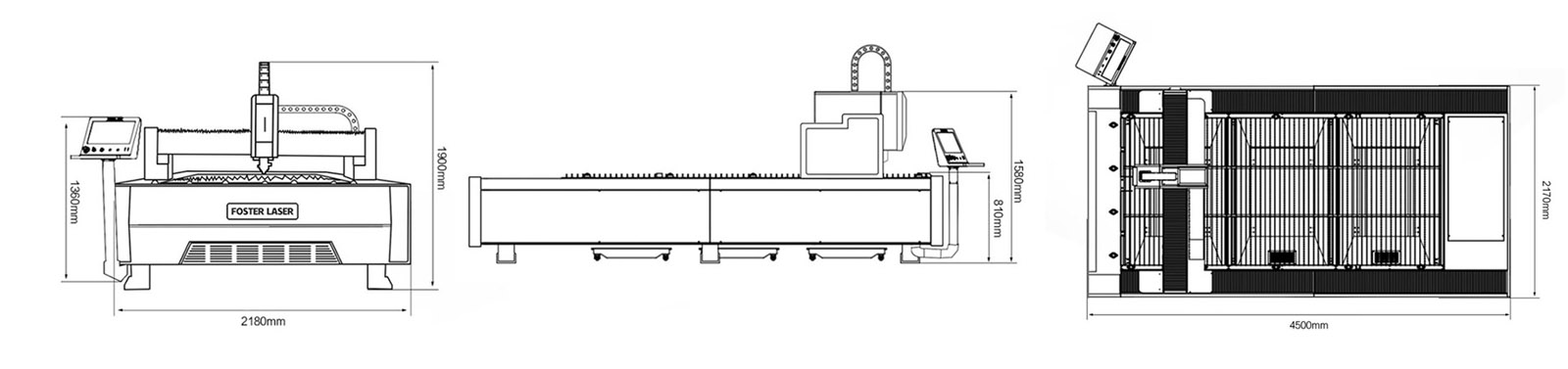

Machine Layout

Famous Brand Fiber Laser Source

Specification

Technical Parameters

Main Configuration

Optional Configuration

Technical Parameters

| Model | FST-FM 3015 Fiber Laer Cutting Machine |

| Working Size | 1500*3000mm |

| Laser Power | 1/1.5/2/3/4/5/6/8/12kw |

| Laser Wavelength | 1080nm |

| Laser Beam quality | <0.373mrad |

| Wbrking Life of Fiber Source | More than 10,0000 hours |

| Position Type | Red Dot Pointer |

| Cutting Thickness | 0.5-10mm Within The Range Standard Precision |

| Max. Idle Running Speed | 80-110M/min |

| Max acceleration | 1G |

| Reorientation Accuracy | Within ±0.01mm |

| Lubrication System | Electrical Motored |

| Cooling mode | Water cooling and protection system |

| Machine power | 9.3kw/13kw/18.2kw/22.9KW |

| Auxiliary Gas for Cutting | Oxygen, Nitrogen, Compressed Air |

| Compatible Software | AutoCAD, CorelDraw, etc. |

| Handle Control | Wireless Control Handle |

| Graphic Format | DXF/PLT/AI/LXD/GBX/GBX/NC code |

| Power Supply Voltage | 220v 1ph or 380v 3ph,50/60HZ |

| Warranty | 2 Years |

Main Configuration

| Model | FST-FM Series |

| Control System | CypOne/CypCut – Friendess |

| Drives and Motors | Japan Fuji Servo Motor System |

| Fiber Laser Head | Raytools Laser Head |

| Fiber Source | Raycus or Max or IPG |

| Lubrication System | Electrical Motored |

| Guide Rails | Taiwan HIWIN Rails |

| Rack and Gear | Taiwan YYC Rack |

| Driver system power | X=0.75/1.3KW,Y=0.75/1.3KW,Z=400W |

| Reducer | Japan SHIMPO |

| Electron Component | DEUXI ELECTRIC |

| Chiller | HaiLi/S&A |

| Voltage | 380V 3Ph, 50/60HZ |

| Gross weight | 1.9T |

Optional Configuration

| Model | Detail |

| Control System | CypCut |

| Drives and Motors | Yaskawa Servo Motor System |

| Fiber Laser Head | RAYTOOLS BM110 Automatic Focus Laser Head |

| Stabilizer | Made in Chinia |

| Exhaust fan | 3KW |

| Wooden packing | With metal bracket |

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Manufacturer Of 6000w Fiber Laser Cutting - Flatbed Fiber laser cutting machine – Foster , The product will supply to all over the world, such as: Switzerland, Brazil, Canada, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.