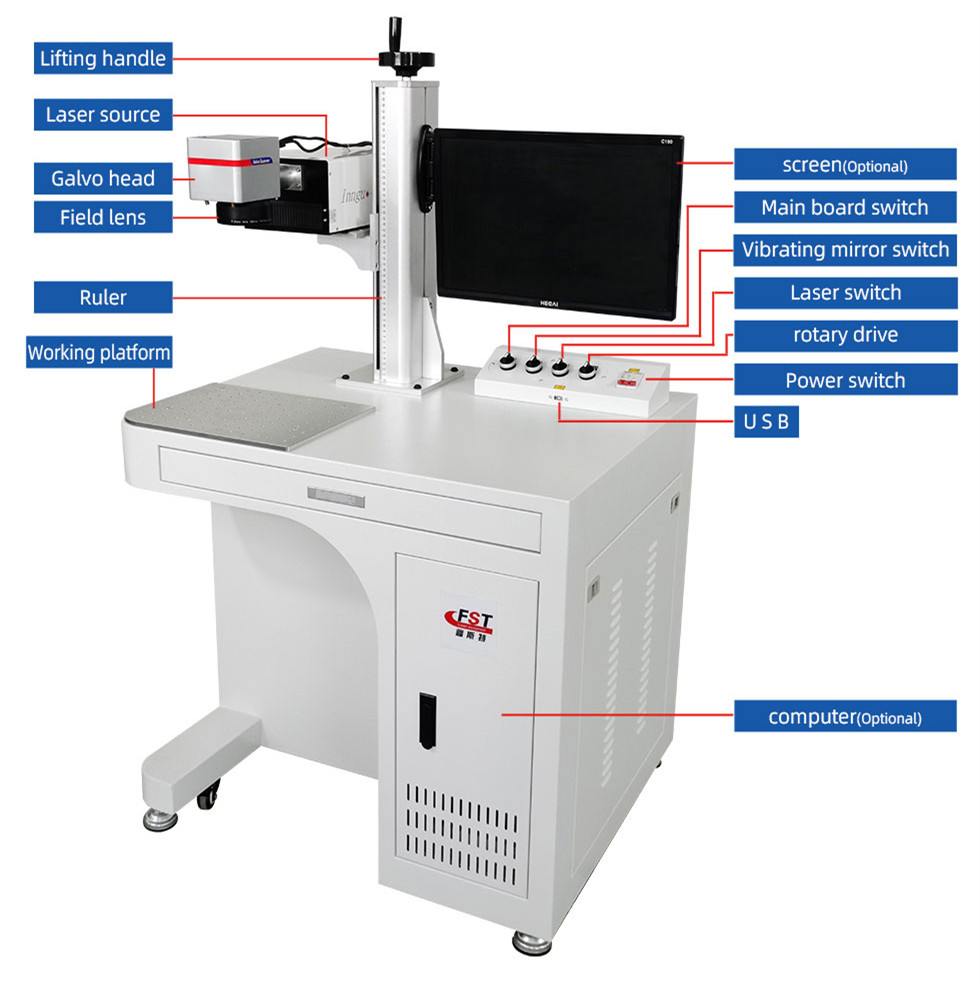

High Stability no Tactile Marking Effect 355nm Laser Device as The Light Source Uv Laser Marking Machine with Superfine Marking

CHARACTERISTIC

1.The machine takes 355nm light laser device as the light source.Ultraviolet laser marking machines have the advantage of limiting thermal stress that other laser machines do not.

2.The heat affected area is very small, will not produce thermal effects, will not produce material scorching problem.

3.The good quality and small focus spotlight could achieve the ultra-fine marking with high speed and high efficiency.

4.Preinstalled high-precision practical multi-functional work surface, the table has a number of flexible screw holes, convenient installation of special fixture platform.

5.The cooling system is air cooling, to ensure that the laser long life, stability, reliable work and other characteristics.

6.High efficiency of the photoelectric conversion and long service life.

PRODUCTINTRODUCTION

Foster Laser UV laser is cold ligh source. UV laser with short wavelength, focus, smaller spot, belongs to cold process with a little heat affecting, good beam quality, it can achieve hyperfine marking.Most materials can absorb ultraviolet laser, it is widely applied on industrials; with very little heat affecting area, it won't have heat effect, there is no burning problem, pollution-free, non-toxic, high marking speed, high efficiency,the machine performance is stable low power consumption.

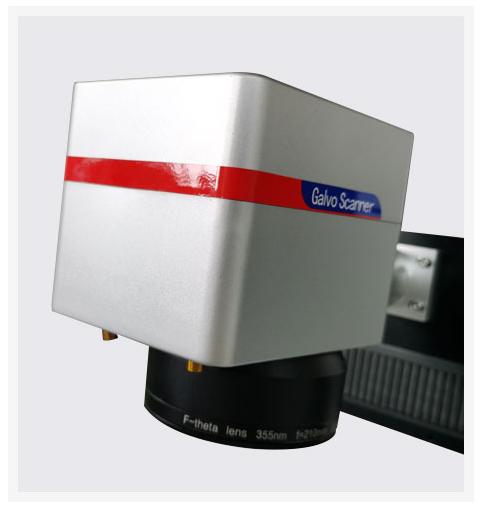

FIELD LENS

We use famous brand to provides precision laser. Standard 110 x 110mm marking area. Optional 150x150mm, 200x200mm, 300x300mm etc. Optional:OPEX etc.

GALVO HEAD

Famous brand Sino-galvo, high speed galvanometer scan adopting SCANLAB technology, digital signal, high precision and Speed.

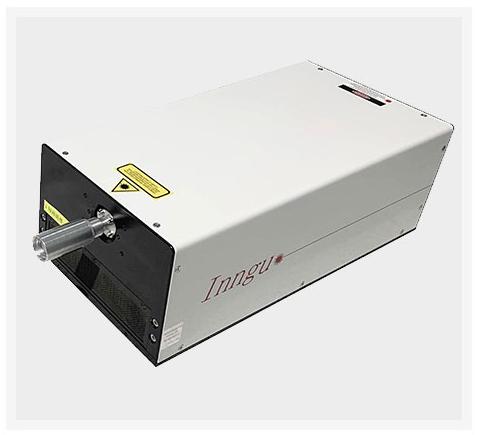

LASER SOURCE

We use Chinese best Ultraviolet laser source brand YINGGU. Optional: Raycus/ Max IPG / JPT

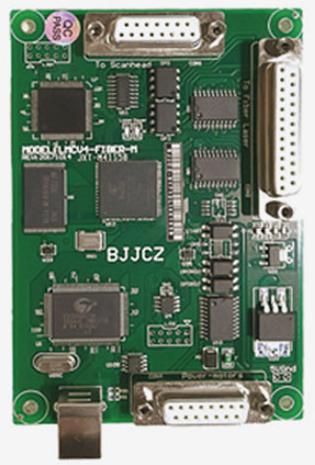

JCZ CONTROL

Ezcad genuine products, userfriendly interface, functional diversity, high stability, high precision. Each board has its own number to ensure that it can be inquired in the original factory. Refuse to fake

Application Industry

1) It is widely used in electronic components, battery chargers, electric wire, computer accessories, mobile phone accessoriesu (mobile phone screen, LCD screen) and communication products.

2) Automobile and motorcycle spare parts, auto glass, instrument appliance, optical device, aerospace, hardware machinery, tools, measuring tools, cutting tools, sanitary ware.

3) Pharmaceutical, food, beverage and cosmetics industry.

4) Glass, crystal products, arts and crafts of surface and internald thin film etching, ceramic cutting or engraving, clocks and watches and glasses.

5) It can be marked on polymer material, majority of the metal and non-metallic materials for surface processing and coating prevention materials etc.. film processing, pervious to light polymer materials, plastic, fire

Product Parameters

| Laser Type | UV Laser Marking Machine |

| Working area | 110*110150*150/200*200/300*300(mm) |

| Laser power | 3W/5W/8W/10W(Optional) |

| Laser wavelength | 355nm |

| Application | metal and nonmetal |

| Marking Speed | 7000mm/second |

| Repeated Precision | ±0.003mm |

| Working voltage | 220V/ or 110V (+-10%) |

| Cooling Mode | Air Cooling |

| Supported graphic formats | Al, BMP, DST, DWG, DXF, DXP, LAS, PLT |

| Controlling software | EZCAD |

| Optional parts | Rotary Device, Lift platform, other customized Automation |

| Warranty | 2 year |

| Package | Plywood |

Our Exhibition

FAQ

Q1: I know nothing about this machine, what kind of machine should I choose?

You don't have to be a laser Expert, let us be the professional one who guide you to choose the right solution. The only thing you need to do is to tell us what you want to do, Our professional sales will give you proper recommendations based just on what you need.

Q2: When I got this machine, but I don't know how to use it. What should I do?

Well. First of all, our machine is designed for easy use. You will know how to use it when you have it as long as you can use a computer. Besides, we will also provide English users manual and installation and operating video. If you still have questions, you are welcomed to contact with us anytime for a online free guiding. Our Professional after-sales engineers are always ready to help.

Q3: If some problems happen to this machine during warranty period, what should I do?

We will supply free parts if your machine is still on warranty. While we also supply free life long after-sales services too. So any questions, please don't hesitate to let us know, we are always ready to help. Your satisfaction is always our greatest pursuit.

Q4: You are warmly welcomed to send us inquiry, in order to recommend the most proper laser solution for you, we are expect to know the following 3 items:

1) Which material you are expect for laser to mark/code?

2) What's the specific character that you are going to mark/code?

3) Do you have any speed requirements? Or what's your current production line feeding speed, so we could check if we could match it.